I was hanging the second of my newly built kitchen cabinet doors, a simple frame-and-panel, paring a hinge mortise when I realized the full weight of the task in front of me. One door hung, one more that would be hung . . . eventually. I shaved off another paper thin layer of wood, then looked up and counted the number of doors that needed to be hung. Only fourteen more to go. I swore quietly to myself and checked the fit of the hinge in its mortise. Continue reading

A Craftsman-style Hall Table–Construction

Construction began with stock preparation. Usually I try to avoid dimensioning stock, but my usual lumber sources don’t carry surfaced quarter-sawn white oak. I thicknessed my stock and set the base material aside to concentrate on the top.

Construction began with stock preparation. Usually I try to avoid dimensioning stock, but my usual lumber sources don’t carry surfaced quarter-sawn white oak. I thicknessed my stock and set the base material aside to concentrate on the top.

The top is a full inch thick, giving it a pleasant heft and accentuating its horizontal line. I took some time arranging boards until satisfied with the design then glued it up and moved on to the base. Continue reading

A Craftsman-style Hall Table–Design

One of the things on our “must have” list when home shopping was an entry way; we didn’t want to walk directly into a living room. Our hall isn’t large, but it provides a transitional space between outdoors and in. And it is big enough for a table and chair, a place to put on shoes or take off a coat. While we had space for a table, we didn’t actually have the table. We wanted something in the Craftsman style scaled to the space. A quick check with the tape measure showed something about 40″ w x 36″ h x 14″ d fit the bill. I flipped through the library looking at every example of hall tables and related designs I could find and put together this design in SketchUp.

An inch-thick top gives the table some heft, and the slats and through tenons ally the design with the work of Gustav Stickley. A telescoping webframe supports three drawers while the bottom shelf creates some additional storage and adds another horizontal line to what might otherwise be a very vertical design.

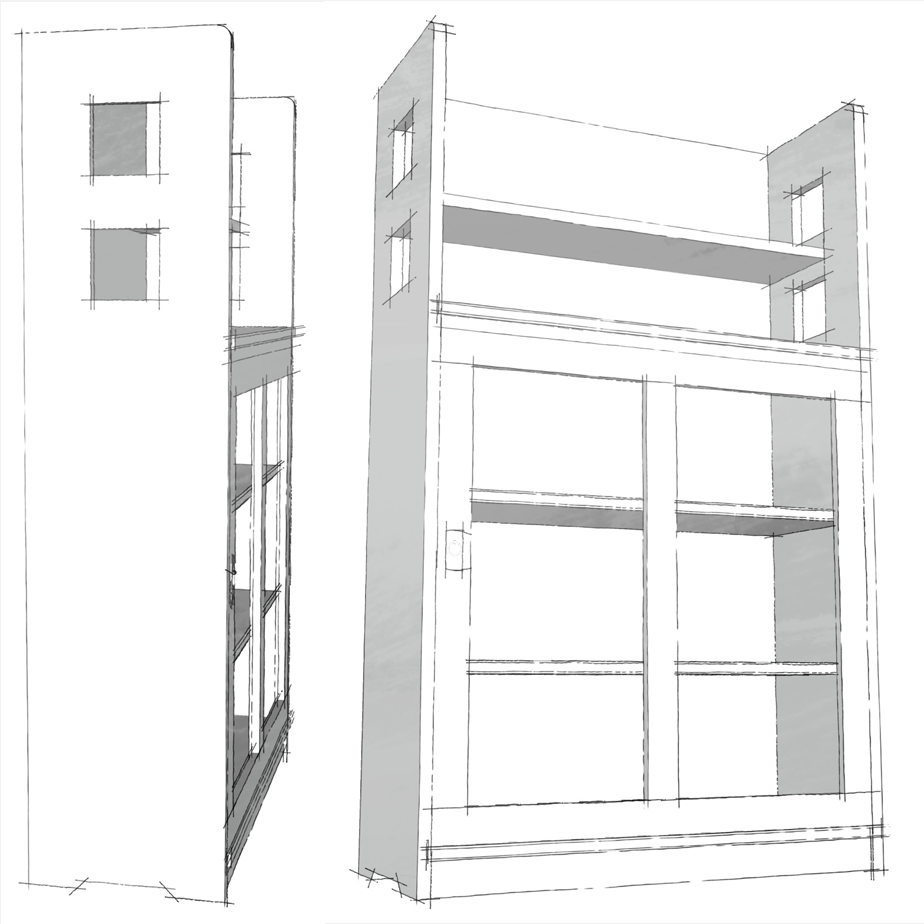

Limbert No. 367 Book Case–Construction

This partial pattern contains all the elements of the case sides without the bulk entailed by a full-sized pattern. It also allows the creation of sides of different heights.

Building the No. 367 is straightforward proposition. Dadoes capture the shelf ends and join the case together while the gallery back helps things square. I made a few modifications to the design, altering the depth from 12″ to 11.25″ to use 1″ x 12″ material, and narrowing the case from 30″ to 24″ since I thought it looked better. I also substituted a shiplapped back for the original’s panel. Having decided on a milk painted finish, I chose pine instead of the fumed white oak used in the original. Continue reading

Limbert No. 367 Book Case–Design

If I were a historian of material culture, I might contemplate the staggering variety of book storage marketed in the early part of the 20th Century and its relationship to an expanding middle class and the rise of mass media. Advancements in printing technology made more books, magazines, and music available to more people, and they could store this material on magazine stands, book racks, book shelves, book cases, etc. Limbert’s Fall 1905 catalogue featured 34 such pieces, from a $4.50 magazine stand to a $54 case with three leaded glass doors. Continue reading

Limbert No. 238 Tabouret

The original version of this side table sold for $7.00 in Limbert’s 1905 catalog. Like other of Limbert’s best pieces, its design transcends the period, making it a bit of chameleon at home with many styles. The original was built of quartersawn white oak with a fumed finish. I chose to build it in cherry following an article from the November 2003 issue of Popular Woodworking.

The project provides a fine introduction to pattern routing since each leg is identical. The article calls for arranging the rabbeted legs in a pinwheel pattern, which makes for an awkward glue up since the parts want to slip when clamped. If I were building another (easy enough to do with the pattern prepared), I might rabbet both sides of each leg to produce a centered tongue, then assemble in stages, beginning with gluing two opposing legs together and finishing by gluing the remaining legs in the grooves formed by the meeting of the opposed tongues.

I began by selecting the best wood (“best” a relative term for the mediocre stock I had on hand) for the top, gluing it up. I then marked out the legs, cut out rough blanks, and used a bearing bit in the router guided by the pattern to cut the legs to final shape. I sanded through 400 grit, taped off the joints, and applied a couple of coats of boiled linseed oil. After glue up, the top was attached using brackets.

More Information

Model in the Sketchup Warehouse

Popular Woodworking’s Arts & Crafts Furniture (Amazon link) collects some of the magazine’s most popular Arts & Crafts projects, including this tabouret.

Michael

April 2, 2013

I’ve been contemplating a credenza build almost since we moved in, a place to store office supplies and files, but it hasn’t been a priority. Recently in between projects, I decided on an interim solution for my storage woes. A small chest of drawers sized to fit on one of my magazine stands could serve to hold the odds and ends that haven’t found a home in my office yet and could be repurposed after that happy day in the future when I’ve built that credenza.

I’ve been contemplating a credenza build almost since we moved in, a place to store office supplies and files, but it hasn’t been a priority. Recently in between projects, I decided on an interim solution for my storage woes. A small chest of drawers sized to fit on one of my magazine stands could serve to hold the odds and ends that haven’t found a home in my office yet and could be repurposed after that happy day in the future when I’ve built that credenza.

A small chest is an interesting project for a number of reasons. The small scale makes it a manageable effort while the joinery involved–drawer and carcase construction, web frames, veneering–can also be used to build larger chests, making it an ideal way to work through the challenges and techniques of chest building before attempting larger pieces. The small scale also provides a chance to use smaller pieces of figured wood. Read more.

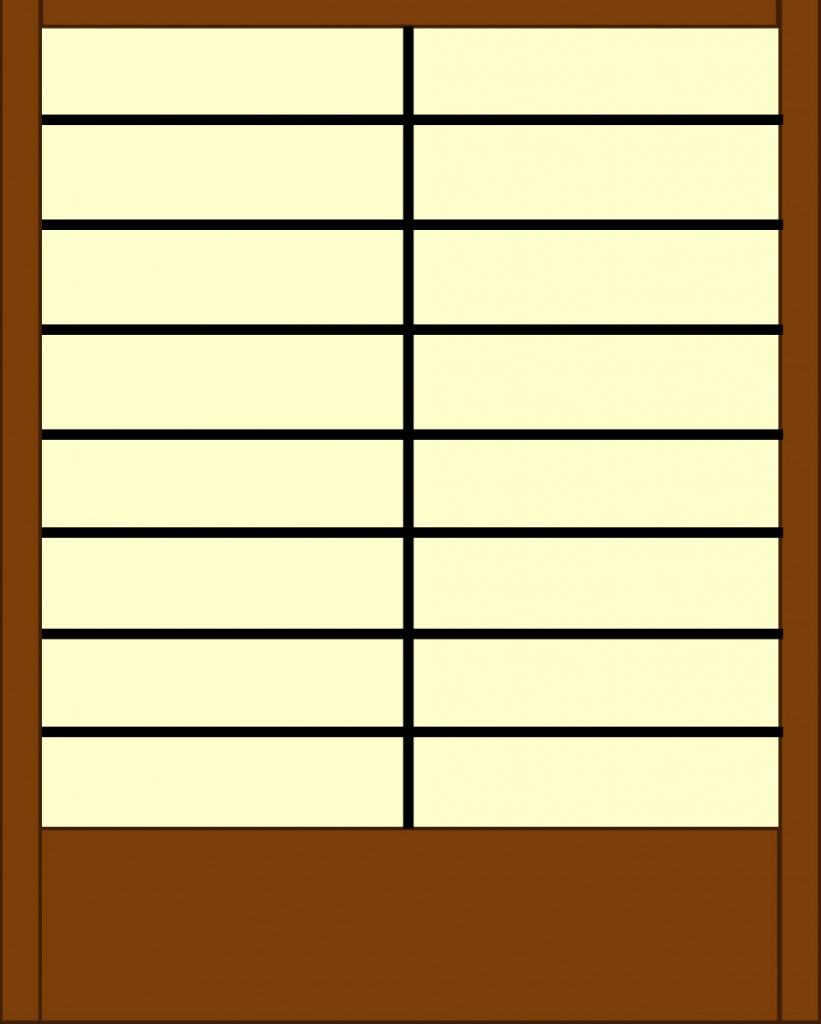

Build a Leaded Glass Panel

Straight cuts allow for plenty of design variation while allowing for easy construction. Here the choice of frame, color of glass, and thickness of came combine to suggest a shoji screen.

On the local Historical Society’s annual tour of homes, we admired the leaded glass paneled doors of a kitchen’s cabinets and decided to do something similar as part of the update to our kitchen. While

cutting and fitting curved pieces requires special equipment, the straight edges used here are easily assembled using only a few additions to common shop tools. Simple variations adapt the panels to a variety of styles, including Craftsman, Prairie, and Asian-inspired.

To build your own panels, you’ll need a glass cutter, straight edge, solder, came, a way to cut the came (I used a power miter saw, but a hacksaw will work), glass, putty, putty knife, and an assembly board, a large rectangle of MDF or plywood with two fences forming a right angle at one corner of the board. The panel is assembled from that corner outward, ensuring tight fitting joints and a square panel as glass and came are added to achieve the desired size. The panel is then soldered and puttied. Read more.

Kitchen–counters and backsplash

Our intention to leave the kitchen remodel for a later date didn’t last much beyond the death of the expiring range a couple of months after we moved in. We bought a new stove and matching OTR microwave. Since there was no cabinet over the wall, I built a couple of plywood boxes and applied a face frame. With the cabinet (the door would wait for a while) and appliances installed, the kitchen looked even more depressing. Fresh paint could go a long way towards lightening the space, but there was still the beige backsplash. And the counters.

We contemplated a staggering array of yellows and the best accent stripe color for the new white subway tile backsplash. I wanted to do soapstone counters since soapstone can be worked with woodworking tools, but the lead time and cost suggested another alternative, one we found in Bungalow Kitchens. Wood counters are period appropriate, and IKEA offers different species at reasonable rates.

With materials and colors selected, we demoed the old backsplash and underlying plaster, installed concrete backerboard, installed the new backsplash using a budget wet saw, removed the old counters, installed new counters, sink, and garbage disposal and painted over the course of a couple of weekends.

New counters, sink, and backsplash. The cabinets still need new doors, and the curlicue trim above the sink must go.

Midtown Sacramento is surprisingly pleasant, with tree-lined streets and late Victorian and Craftsman homes still dotting the landscape. These caught my eye on my walk to the office on a recent business trip.