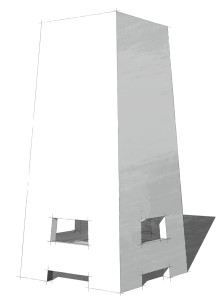

The base of the No. 239 tabouret reminds me of the No. 254 umbrella stand.

I’d leaned the sides of the tabouret against the bench to get them out of the way to begin work on the corbels when something in their shape seemed familiar. Because the Limbert Furniture Company produced so many designs featuring the tapered column base, it took me a minute to realize why these sides look familiar: They are very similar to the the shape of the No. 254 umbrella stand. The stand may have a slightly wider mouth than the table, but both share the same footprint and similar cutouts, though the tabouret features two cutouts the stand’s one. It would be easy to repurpose the template I created to build the umbrella stand, either preserving both cutouts or omitting the second. The umbrellas probably won’t mind if I’m not 100% accurate to the original.…

More Information

The No. 254 Umbrella Stand is one of thirty-three Limbert designs featured in my first book, Building Classic Arts & Crafts Furniture, available on Amazon and Shopwoodworking.com.