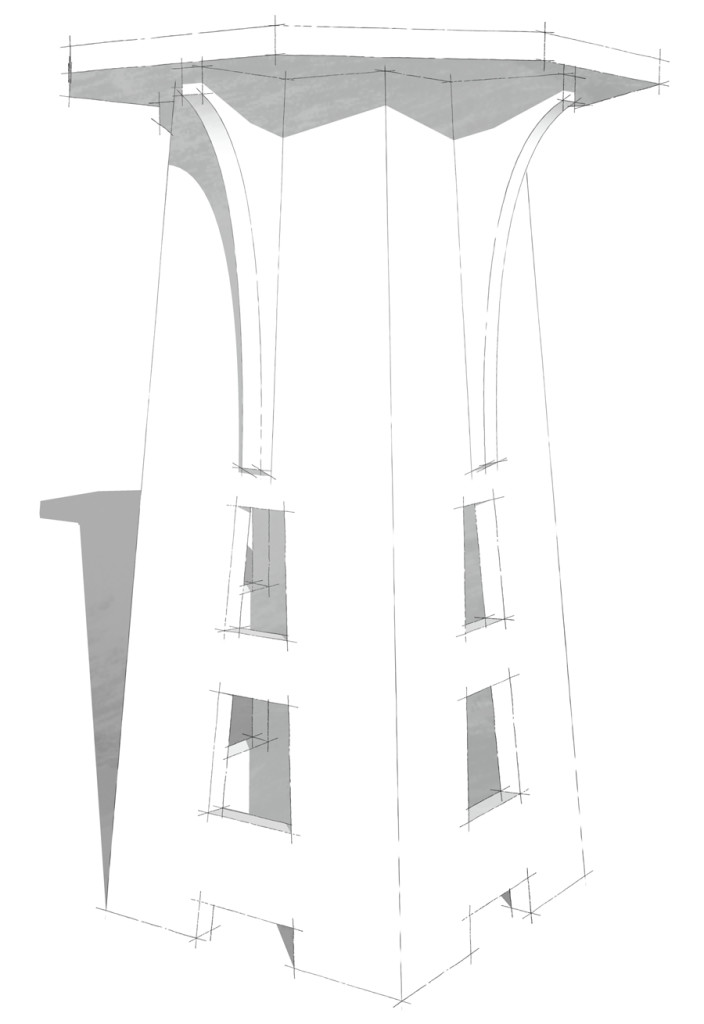

While the tapered columnar base looks a bit elaborate, building it is relatively straightforward. I produced a pattern then used it to bring the sides to final shape, cut their mitered edges, and plow the grooves for the corbels. After roughing out the side blanks, I then routed them to final size with a pattern bit and mitered the edges with a 45-degree chamfer bit. A a 3/4-inch guide ring kept the ¼-inch spiral upcut bit straight as I plowed the grooves.

I took my usual approach to corbels, then cut the top to final size and chamfered its edges lightly. After sanding things to 220 grit, I fumed the table and applied a coat of boiled linseed oil. While I generally prefer to prefinish my parts that decision here proved problematic: packing tape does not stick to oiled wood. I had to scramble during assembly, replacing packing tape with masking tape and a couple of strategically-placed clamps. Despite this obstacle, I managed to get the base together, then installed the corbels, using a shaped caul and clamps to glue each one in place. Screws through corner brackets attach the top to the base.