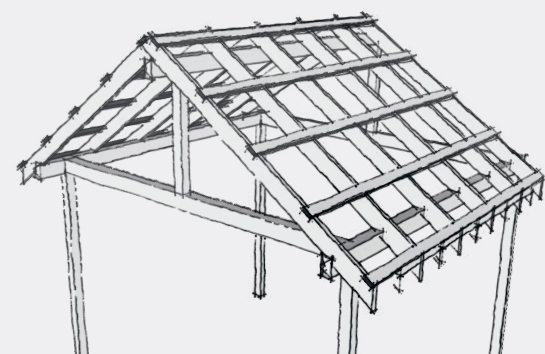

The roofing panels I selected required purlins 24 inches on center to prevent sag. Initially, I’d considered installing blocking between the rafters, but after reviewing timber frame images with purlins that ran over the rafters, I drew versions with blocking and overlaid purlins and decided half-lapped purlins looked better than blocking or a simple overlay.

To cut the half laps, I laid out the joints on 2 x 6 stock and used a straight bit in the router guided by a dado jig to notch the stock. After cutting the joints, I ripped the 2 x 6 stock into 2.5 inch strips and rounded over the cut edges with a 1/8″ roundover bit.

After the joinery, installation was easy. The first purlin was set in place at the end of each rafter and screwed into place at every joint. I then used spacer blocks to position the next purlin and fastened it in place. Repeat ten more times, and the porch was ready for a roof.